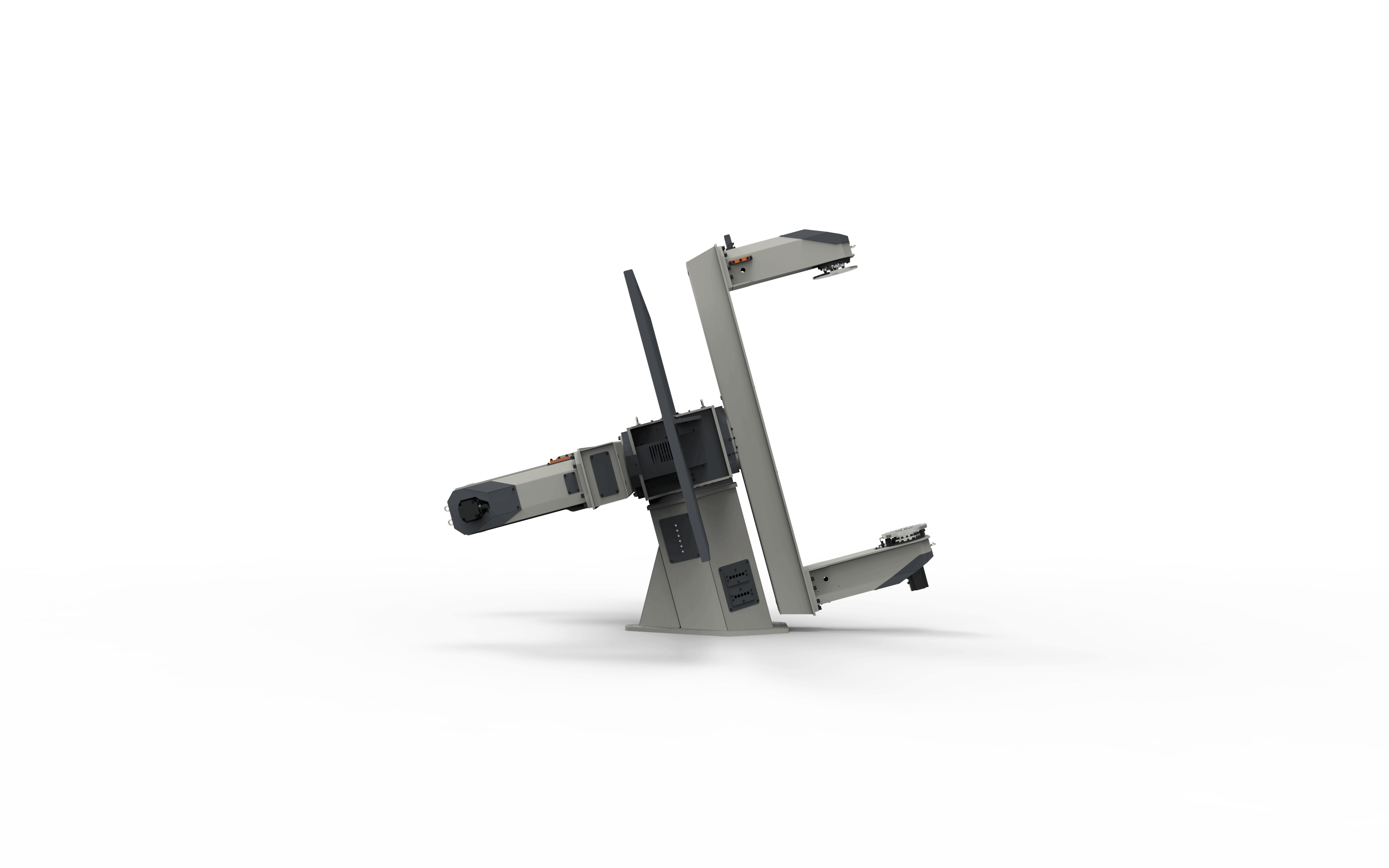

SPN-UUB Series 5 Axis Positioner.

While the robot welds at the station in front of it, the operator loads parts at the other station. With the 180 degree rotation of the index axis, the stations are changed.

Two rotating axes in the station positioned in front of the robot always bring the workpiece to the ideal welding position.

Welding a workpiece always in the ideal welding position (PA), that is, in a position where the torch is positioned in the direction of gravity and the lateral flow of the weld pool is minimal, provides both productivity and quality increases.

Perfect positioning allows to increase welding speed and prevents under cut formation.

ADMEX SPN-UUB positioners are the highest level positioners in many fields such as automotive, general machinery, construction machinery, agricultural machinery with high speed, precision and rigidity.

It should be preferred especially for welded constructions operating under dynamic loads such as chassis parts such as rear axles and axles of vehicles, booms, arms, buckets, fuel and oil tanks of construction machines, and all load-bearing elements of agricultural machinery.

Like all other ADMEX positioners, SPN-UUB series positioners have been optimized with long-term FEA studies. The standard elements used were selected from the leaders of their class.

With current flow up to 1600ampere, 4 robots can work together in single wire welding or two robots with twin welding at the same time.

ADMEX positioners are developed to be user-friendly. They do not require maintenance with the automatic lubrication option. With the ADMEX special brush technique, there is no problem of welding chassis transfer. All axes provide the required rigidity and precision in the most perfect way with pre-stressed and gapless bedding.